What You’ll Learn

How can I create a preliminary crane budget that avoids surprises and keeps my project on track?

For project estimators, the key is accounting for all costs associated with crane operations—not just the base rental rate.

With detailed pre-lift planning, you can build budgets that are accurate and realistic.

In this blog:

Your preliminary estimate didn’t look so bad.

With that number in mind, you gave the project the green light.

Except, now that the project is done, you’ve been handed a bill dramatically higher.

Your estimate wasn’t accurate in the least.

Why Preliminary Estimates Often Miss Key Crane Costs

Crane costs are deceptively complex. It’s easy to focus on the “rate per hour,” but that number rarely reflects the full scope of what the crane rental actually entails.

Hidden or overlooked costs can include:

- Rigging equipment weight and setup

- Ground preparation and safety matting

- Certified operators and riggers

- Mobilization and demobilization

- Permit fees and traffic management

Failing to account for these factors can result in under-budgeting, project delays, or unexpected expenses mid-lift.

Total Load Matters

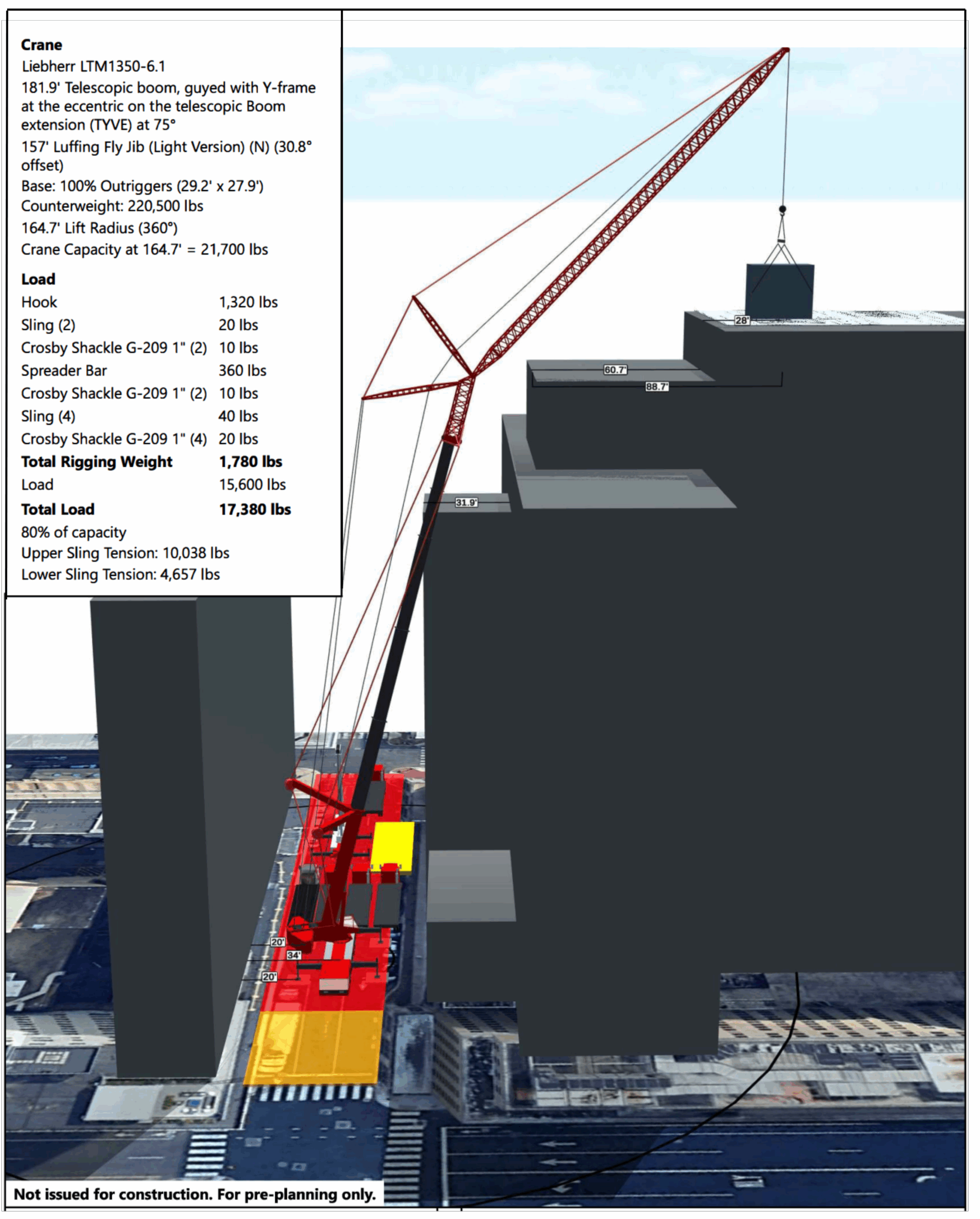

One of the most overlooked areas in preliminary budgeting is the total load a crane must lift.

This includes:

- The actual object being moved

- Slings, shackles, spreader bars, and other rigging equipment

- Load distribution considerations for specialized materials

- Any ancillary attachments or fixtures

For example, a rooftop HVAC unit might weigh 5,000 pounds, but the rigging and spreader bars can add hundreds of pounds more. If the total load isn’t accounted for, you could specify a crane with insufficient capacity.

A crane partner who helps you calculate the total load ensures your budget reflects the correct crane size and avoids costly last-minute equipment swaps or lift adjustments.

Specialized Safety Requirements Drive Cost

Every job site has unique conditions that affect crane setup and cost. Some of the most critical safety-related factors to consider include:

- Ground bearing pressure: Soft soils may require mats or cribbing to distribute weight safely.

- Matting and stabilization: Protecting surfaces and providing a stable base for the crane can involve additional materials and labor.

- Environmental hazards: Overhead lines, nearby structures, or uneven terrain may require extra rigging or safety measures.

Ignoring these requirements can compromise safety and create unplanned expenses. Budgeting for safety isn’t optional. It’s mandatory.

A crane partner with experience in pre-lift safety planning will advise on the proper ground preparation, matting, and rigging solutions, ensuring that your budget accurately reflects these costs upfront.

Certified Personnel Are Essential & Add to the Cost

The crane itself is only one part of the cost equation.

Operators and riggers are certified professionals whose expertise directly impacts safety and efficiency:

- Operators control the lift and are responsible for its execution.

- Riggers handle slings, shackles, spreader bars, and load attachments.

- Both are trained to respond to real-time challenges like wind shifts or unexpected load movement.

When calculating crane costs, make sure to include personnel costs.

Using a crane without certified personnel might lower the rental rate on paper, but it introduces risk and potential liability that can far exceed any savings.

Why a Detailed Pre-Planning Lift Plan Reduces Estimation Surprises

The most cost-effective way to eliminate surprises is to work with a crane partner who provides comprehensive pre-lift planning.

A thorough lift plan includes:

- Crane placement and setup requirements

- Load weight and rigging calculations

- Lift radius and boom configuration

- Safety measures, including mats, cribbing, and traffic management

- Contingency plans for wind, weather, and site constraints

With this level of detail, estimators can accurately account for every cost component—equipment, personnel, safety, and logistics—before the project starts.

This preparation prevents mid-project budget overruns caused by unforeseen lift complications.

How Active Crane Helps Estimators Integrate Total Crane Costs

At Active Crane, we understand the unique challenges faced by project estimators.

Our comprehensive service model ensures you can integrate crane costs into your preliminary budget with confidence:

- Total load analysis: We help calculate every pound to ensure the crane selected can handle the full lift, including rigging weight.

- Safety assessments: We provide recommendations for mats, cribbing, and ground preparation based on actual site conditions.

- Certified personnel included: Operators and riggers are fully certified, so you can account for labor costs accurately.

- Pre-lift planning: Our detailed lift plans outline equipment needs, logistics, and safety protocols, giving you a clear picture of costs upfront.

- Transparent estimates: No hidden fees—every line item is included, so your preliminary budget matches the actual project expenses.

Working with a partner like Active Crane not only simplifies the budgeting process—it reduces risk, prevents delays, and protects your project’s bottom line.

Avoid Estimate Surprises with Active Crane

The key to avoiding surprises is working with a crane partner who provides full pre-lift planning and transparent cost breakdowns.

Active Crane helps estimators account for every cost factor in crane operations—from total load and rigging to safety requirements and certified personnel.

Request an estimate today and take the first step toward a safer, more accurate project budget.

FAQs

What is included in the total cost of a crane rental?

The total cost includes the crane rental rate, rigging equipment, certified personnel, mobilization, site preparation, safety matting, permits, and potential traffic or logistical fees.

Working with a crane partner who provides detailed planning helps ensure all these costs are accurately reflected in your budget.

Why should rigging weight be included in cost estimates?

Rigging equipment—like slings, shackles, and spreader bars—adds weight to the lift and can affect crane capacity requirements.

Failing to account for rigging weight can result in underestimating the needed crane size and lead to last-minute changes or safety issues, increasing overall project costs.

How do site-specific safety requirements impact crane costs?

Ground bearing pressure, matting, cribbing, and environmental constraints all affect crane setup.

Estimators must budget for these specialized safety measures, as ignoring them can result in delays, damage, or regulatory non-compliance.

Detailed pre-lift planning ensures all safety-related costs are included upfront.

Why is including certified personnel important in crane cost estimates?

Operators and riggers are trained professionals essential for safe crane operation.

Their expertise is a budgeted cost that ensures lifts comply with regulations, avoid accidents, and minimize downtime. Omitting personnel costs can lead to underestimated budgets and potential liability issues.

How does a pre-lift planning process reduce estimation surprises?

A comprehensive pre-lift plan outlines total load, crane placement, rigging, safety measures, and potential contingencies.

By reviewing all equipment, site, and personnel needs in advance, estimators can account for every cost, preventing unexpected expenses and ensuring the project stays on budget.

Recent Comments